- Home

- Competence center

-

Smart Manufacturing & Quality

Smart Manufacturing & Quality

Impresoft’s answer to Industry 4.0

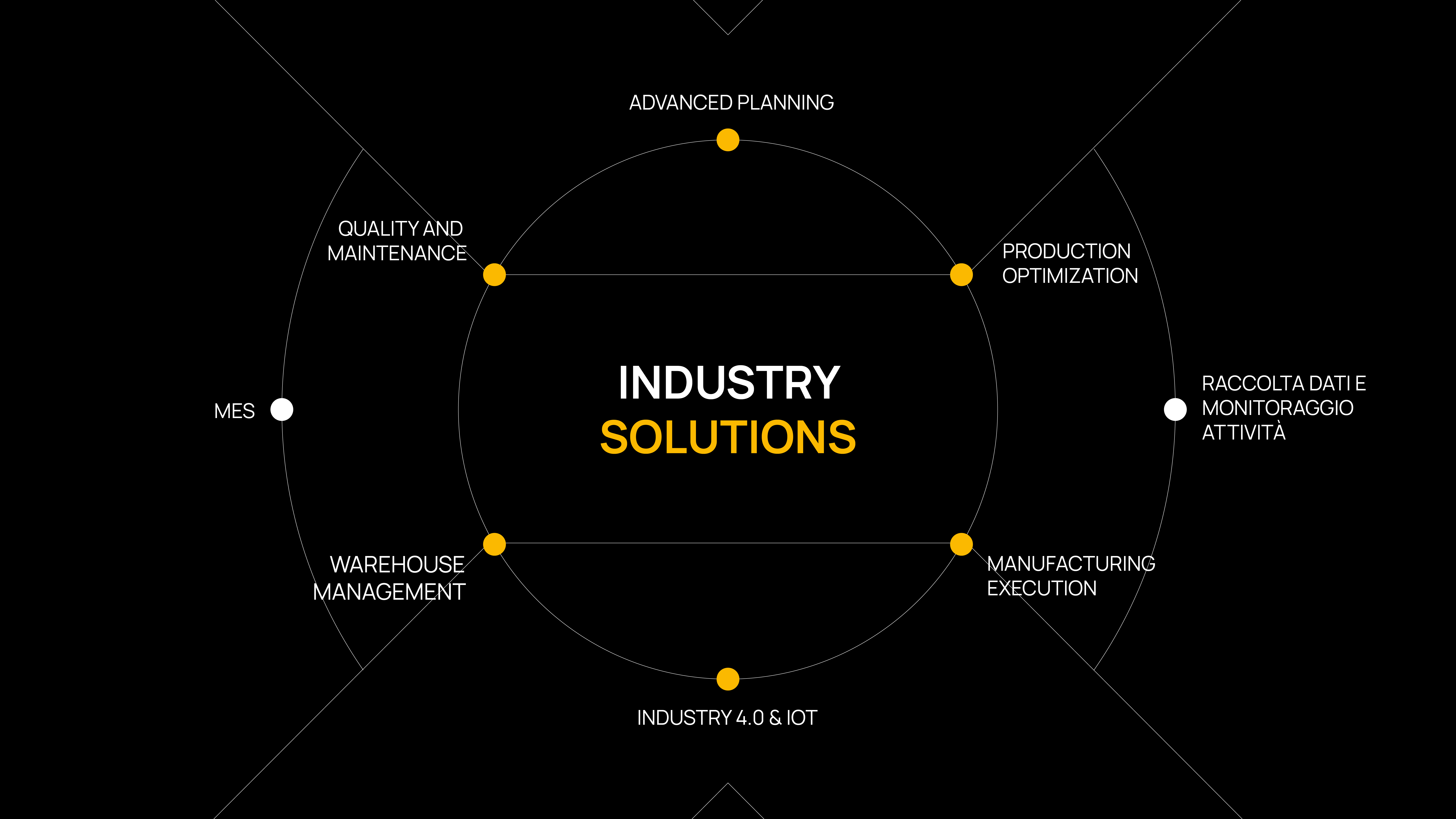

Solutions for manufacturing industries that want to improve factory process efficiency and competitiveness. Adoption of MES in manufacturing plants and use of all accompanying tools, such as AdvancedHMI, which enable pervasive control of factory facilities. The result is higher quality finished products with a drastic reduction in waste, a significant reduction in machine downtime, optimisation of maintenance operations and a shorter time to market.

The aim is to monitor production performance, collect and correlate information, automate processes through the management, organisation and control of interactions between machines and factory operators; optimise and digitise set-ups, collate incidents, and monitor downtimes and non-conformities - all with a view to increasing competitiveness and making manufacturing companies more efficient.

But above all, we want to support manufacturers in their digital transformation projects to enable them to generate value from company data and create smart factories through the implementation of the MES system NET@PRO.

Dialogue.

Consulting that designs the digitisation roadmap of your factory according to your needs.

Partnership.

We are your IT partner for smart factory and IoT project development with an end-to-end approach.

Technology.

We use the NET@PRO suite for production management, control and planning.

A consolidated and reliable solution

MES

This is software used in the manufacturing industry to monitor and manage production processes in real time. It integrates with other business systems such as ERP and quality control to provide a global view of production activities.

APS

This is used by industries to optimise production planning, order management and stock control. It takes into consideration factors such as production capacities, available resources and order schedules to generate an optimal production plan.

WMS

This software manages warehouse logistics, tracks the movement of goods, keeps track of stock availability, monitors inventory, organises goods and tracks shipments. It also improves operational efficiency by integrating with other applications.

Quality

A platform that manages product or service quality processes in an automated way. Its functions include the definition and organisation of controls, proactivity in the event of deviations, the creation of KPIs and reports, data management, communication between users and native integration with the factory system.

CMMS

A tool that helps companies plan and manage the preventive and corrective maintenance of their machinery. The software allows you to set preventive maintenance schedules, and keeps track of the maintenance activities carried out and any repairs or replacement parts used.

Industry 4.0

Interconnecting machines, devices and systems through IoT, data analysis, machine learning and artificial intelligence. All this enables you to create an intelligent and predictive factory that can monitor, analyse and optimise production processes in real time.

Activity Management

Manages unstructured processes, and projects in general, reducing communication time and anticipating possible information misalignments. It forces any misunderstandings that could arise between personnel from different departments to be addressed as quickly as possible. It also allows you to create teams to which you can assign projects.

Costs

Production can be monitored with a focus on costs by gathering accurate data on the production process and generating detailed reports on the prime cost of production for each product. This allows companies to quickly identify areas where they can reduce costs or where they are producing at a higher than budgeted cost.

MES NET@PRO

LIMS ProLab

QMS QuartaEVO